Dynamo I - Generator - Alternator 12V/150W

Original Auto - Lite

Dear Sir or Madam,

We would like to take this opportunity to introduce our new product.

The Dynamo I project, a replacement for Auto-Lite models GAS-4102, 4104, 4131, 4132, 4151, 4152, 4159,

4166, 4170 and GDE-4101, 4102, 4104, 4106, 4107, 4108, 4131 is another addition to our broad range of

replacement generators for vintage motorcycles.

The dynamos we offer in 6 V and 12 V versions have already proven themselves in practice on many British, German,

Russian, and Polish motorcycle brands, which led to the development of a complete series of dynamos of types B, C, J,

L, Z, LB, and HD.

Our dynamos have been working reliably for years on all motorcycle models and successfully replace original

generators from Bosch, Lucas, and others.

Owners of Indian motorcycles were also searching for a replacement for their generators. They contacted us, provided

samples of the original GAS and GDE generators, and defined the requirements that the future DYNAMO I should

meet.

Based on our many years of experience, we accepted the challenge and began developing a device that had to meet the

following criteria:

Dimensional compatibility with the original generator.

- High aesthetic accuracy: the unit had to look virtually identical to the original and blend

harmoniously into the motorcycle.

- Improved electrical performance (voltage and power): while the original generators barely reach these values

at maximum engine speed, the Dynamo should deliver them already during relaxed city riding.

We have fulfilled all these requirements.

The core we had previously developed with a ½-inch offset could not be used for this project.

The work had to begin with a complete redesign of the core as well as the entire construction to meet the above-

mentioned requirements.

Based on the dimensions of the original generator and the rotational speed ranges achieved in practice, a core/rotor

assembly was designed and tested on a test bench. As is often the case, the first prototypes did not fully meet our

expectations. However, they provided a clear picture of the situation and data indicating the direction in which

development needed to proceed so that the device would achieve the required electrical parameters within the

specified speed ranges. After five redesigns, we finally arrived at the target design that meets all requirements.

Once we had a power-generating device, we gave it the shape and appearance of the original Auto-Lite Indiana

generator.

Our unit matches the original generator in most dimensions and closely resembles its original appearance.

The voltage regulator housing is styled after the original, but was modified accordingly due to the need to

accommodate our own regulator solution. Anticipating questions about using our regulator in original generators: this

is absolutely not possible, as our unit is not a brush-type generator.

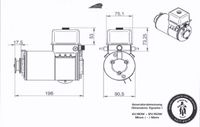

Generator Dimensions:

- Length: 7,71 inch

- Diameter: Ø 3,56 inch

- Mounting flange: 0,69 inch

- Weight: kg

Electronic Regulator Dimensions:

- Length: 2,96 inch

- Height: 2,88 inch

Technical Specifications:

- Voltage: 12 V / 150 W

- 3-phase AC generator

- No-load voltage: 14.4 V at 1200 rpm

- Voltage under 80 W load: 14.4 V at 1500 rpm

- Negative ground (–)

- Electronic regulator installed on the generator, precisely matched to Dynamo

Technical Requirements:

- Negative ground (–)Battery: 12 V, minimum 10 Ah – gel, acid (lead-acid), or lithium batter

- Fuse 15A

Dynamo I – Indian

The housing has external dimensions that match the original generator. It consists of a tube with a diameter of 3,56

inch and two cast end covers modeled after the original Auto-Lite generator, with the necessary modifications to

accommodate our internal solutions. A band is mounted on the rear part of the housing, designed in a similar visual

style.

We manufactured the rotor with a taper based on the original design, allowing both our own pulleys and sprockets as

well as original ones to be installed. The rotor is made of steel with enhanced strength properties and has undergone

thermo-chemical treatment. It is fitted with neodymium magnets designed to operate at temperatures up to 150 °C.

After testing, we observed that the device temperature does not exceed the engine temperature, averaging about 50–

60 °C. Even on a hot summer day under heavy engine load, we estimate a maximum of around 80 °C, providing a

significant temperature safety margin for the magnets.

To achieve the required output power, we used neodymium magnets, which create resistance when the rotor is

turning.

Anticipating the question:

The rotor advances in a characteristic stepping motion while rotating, unlike a non-energized generator. An energized

generator producing similar power to the Dynamo would create the same resistance on the rotor.

The device has no brushes, which are a common source of problems and failures in conventional generators.

We assumed that an output of 150 W would cover the power requirements of all motorcycle consumers with a

generous safety margin.

The voltage regulator we developed is housed in a casing styled after the original Auto-Lite regulator, but slightly

larger. This is due to a number of technical solutions required by our device.

Voltage Regulator

The voltage regulator of our design operates on a different principle than most regulators available on the market,

which short-circuit the stator windings when the charging threshold is exceeded, creating maximum resistance for the

device and heating the windings, which in the long term leads to their damage.

Our solution disconnects the windings when power is not required and automatically adapts to the current power

demand. Simply put: if the device is loaded with 10 W, it produces only 10 W without overheating the windings. When

demand increases, the regulator adjusts the power generated by the Dynamo accordingly.

Intelligent regulator.

The regulator is mounted on the clamp band, and the phase wire connections are secured to the terminal strip under

the regulator cover. This can be done by the user when replacing the regulator or changing polarity.

This allows the device to be converted from 6 V to 12 V or vice versa by purchasing a different voltage regulator.

The 12 V versions are marked with green nameplates in accordance with American automotive standards, while

the 6 V versions are marked with red nameplates.

Battery

The battery should be selected so that its capacity matches the maximum output of the dynamo. A generally accepted

rule is that the capacity in ampere-hours (Ah) should be approximately one tenth of the device’s power output (with a

tendency toward higher values for the 6 V version):

- For the 12 V version, a battery with a minimum capacity of 10 Ah is recommended.

- For the 6 V version, a battery with a capacity of 8 Ah is recommended.

With the new voltage regulator, all battery types can be used except gel batteries. A distinction must be made between

a gel motorcycle battery and a gel battery such as those used in alarm systems. Many people make the mistake of

purchasing a gel battery instead of a proper motorcycle battery.

In practice, lithium-ion batteries or lead-acid batteries using AGM technology (Absorbent Glass Mat) currently

perform best. Of course, traditional lead-acid batteries from reputable brands can also be used. From personal

experience, I can recommend a lithium-ion battery from Moretti that has proven reliable for over three years.

Our observations show that manufacturers of traditional lead-acid batteries follow a principle of a “one-year product

lifespan.” It has happened that a new lead-acid battery worked for about one year under normal motorcycle

conditions, and a spare battery that sat on a shelf connected to a maintenance charger also remained functional for

only about one year. Both failed after roughly one year. The conclusion was that these batteries have a similar lifespan

regardless of whether they are used or not. After a certain time, they fail suddenly and must be discarded. Similar

experiences have also been reported by our customers.

It should also be noted that a battery installed in an Indian motorcycle is exposed to vibrations. Lower-end batteries

may not withstand these vibrations. The cells inside the battery can loosen or break, causing immediate failure.

Lithium-ion batteries and lead-acid batteries in AGM technology are more resistant due to their construction.

Wiring / Connection Cables

The Dynamo I features a built-in electronic voltage regulator:

The connection is made by attaching the positive wire (+) to the appropriately marked output of the regulator.The

ground wire for the charge indicator light is connected optionally, if the motorcycle is equipped with a warning light,

to the corresponding output of the voltage regulator.The positive (+) terminal of the indicator light is powered from

the ignition switch.The Dynamo I has the negative (–) terminal connected to the housing, which must be connected

to the vehicle’s ground.

Installation of the Dynamo

(1) Carefully read the warranty card.

(2) The wiring diagram of the device is compatible with the original schematics of the individual Indian motorcycles.

It is sufficient to correctly connect the positive wire (+) to the appropriately marked terminal and ensure a proper

connection of the negative (–) terminal to ground – the Dynamo I housing – as shown in the diagram.

(3) For operation with the Dynamo, a battery with a minimum of 10 Ah for the 12 V version (8 Ah for the 6 V version)

is required.

Under no circumstances should gel batteries be used, such as those employed for home alarm

systems.

For conventional batteries, a hose must be installed to vent electrolyte fumes, with the outlet positioned below the

edge of the rear fender.

(4) The device operates with the negative (–) connected to ground. The battery terminal marked as negative (–) must

be connected to the motorcycle frame with a cable of at least 1.5 mm² cross-section. The cable should be fitted with

copper or brass terminals and ideally soldered at the connection point to the wire.

(5) The Dynamo I has the negative terminal connected to the housing. It must be checked that the housing has a

stable ground connection to the motorcycle frame.

(6) The negative (–) wire for the charge indicator light is the ground wire indicated in the diagram.

(7) If no indicator light is present, no additional connections are required; the charge status is indicated by the

ammeter built into the motorcycle console.

After proper connection, the charge indicator light, powered from the positive (+) side, should illuminate.

WARNING: The indicator light will illuminate (and function correctly) only if the battery is connected and the

negative (–) terminal is grounded (see point 4). Reversing the battery polarity (connecting negative to positive

ground can permanently damage the voltage regulator, which is not covered by the warranty!

The charge indicator light will not illuminate if:

- The voltage regulator is not connected to the battery with both positive and negative wires;

- The battery is not connected with the positive terminal to the vehicle ground;

- The indicator light socket is damaged, the bulb does not make proper contact in the socket, or the bulb is burned out;

- Voltage is applied to the wire marked F (negative output from the regulator to the charge indicator), which can

permanently damage the control element of the indicator light. In this case, the charging system works correctly, but

the indicator light either stays on continuously or does not light at all. This often occurs when changing the bulb

under power or during service work on the light while powered, where poor access can easily cause a short circuit.

The correct function of the circuit can be checked by holding the end of the F wire against the Dynamo I housing. The

idle indicator light circuit can be tested by connecting the wire to the vehicle ground; the indicator light should then

illuminate. If it does not, the cause should be checked in the indicator light socket or the connections in the light itself.

If the indicator light does not work, troubleshooting should begin by checking the bulb installed in the idle indicator

light.

(8) The Dynamo is a replacement for the original generator and is installed exactly according to the correct mounting

procedures for the original generator.

Note:

Many customers ask whether it is normal to feel characteristic detent movements when manually turning the gear on

the Dynamo rotor.

Yes – the device contains permanent magnetic elements that cause this effect during rotation. This is completely

normal and not a sign of bearing damage.

An energized original generator also produces noticeable resistance on the gear when generating corresponding

power.

► Included in Delivery:

- Dynamo I

- Warranty card

- Operating manual

- Packaging

Warranty: 3 years

We also provide, free of charge and by arrangement, either a pulley or a sprocket.

When placing your order, please specify your preferred option.

---------------------------------------------------------------------------------------------------------------------------------------

INFO !

Outside EU without 19% VAT, will be deducted from the price in the invoice!

Prices including 19% VAT

Dynamo I

Part number: 00 2376 4I 12 - Dynamo I - 12V/150W - 730,00 € - ►Order

---------------------------------------------------------------------------------------------------------------------------------------